IIT Tirupati organised a two-day Symposium on challenges in the production of 2G Bioethanol. The Symposium was inaugurated by Shri. Kushal Banerjee, Chief General Manager, Hindustan Petroleum Corporation Ltd. Mumbai. Prof. K.N. Sathyanarayana, Director of Indian Institute of Technology, Tirupati and Mr D.M. Giri, CEO of ASN Fuels Pvt. Ltd., were the Guest of Honours of the symposium, which was inaugurated in a webinar keeping the current covid conditions in mind.

The two-day long symposium was organised by Dr Sunil Kumar, Department of Chemical Engineering, IIT Tirupati in association with ASN Fuels Pvt. Ltd., a start-up based out of Bangalore. The objectives of the symposium were to discuss and debate how 2G Bioethanol can be made a reality. The main idea of the symposium was to help exchange ideas, learn cross-discipline insights, develop research conglomerates and provide investors with a platform to promote bioethanol research and implementation. This Symposium brought together many experts in Bioethanol and biofuels in general from various parts of the Nation to share their experiences.

Global demand for fuel efficiency, environmental concerns and energy security have attracted global attention towards liquid biofuels, such as bioethanol and biodiesel. Around the world, governments have introduced various policy measures, mandatory fuel blending programmes, incentives for flex-fuel vehicles and agricultural subsidies for the farmers.

In India, the government launched Ethanol Blended Petrol (EBP) programme in January 2013 for 5% ethanol blended petrol. The policy had a significant focus on India’s opportunity to agricultural and industrial sectors with the motive of boosting biofuel (bioethanol and biodiesel) usage and reducing the existing dependency on fossil fuel.

The government has set targets of 10 per cent bioethanol blend of petrol by 2022 and to raise it to 20 percent by 2025 under the ethanol blending programme to curb carbon emissions and reduce India’s dependence on imported crude oil. The 1G and 2G bioethanol manufacturing units will play a key role in making bioethanol available for blending but face challenges in attracting investments from the private sector it has.

India has advanced the target date for achieving 20% ethanol-blending in petrol by five years to 2025, Prime Minister Narendra Modi announced this in June 2021, as the world’s third-biggest oil importer looks to cut carbon emissions and reduce reliance on foreign oil.

Ethanol extracted from sugarcane and damaged food grains such as wheat, broken rice and agricultural waste is less polluting. Its use also provides farmers with an alternate source of income.

Speaking at a release of ethanol blending road map 2020-25 on the occasion of World Environment Day, in June, Mr Modi had said that the target for mixing 20% ethanol in petrol had been brought forward from 2030 to 2025.

Ministerial announcements regarding E-20 fuel where 20% of petrol is blended with ethanol have further motivated the researchers and entrepreneurs to develop indigenous technology on a Need-of-the-hour basis.

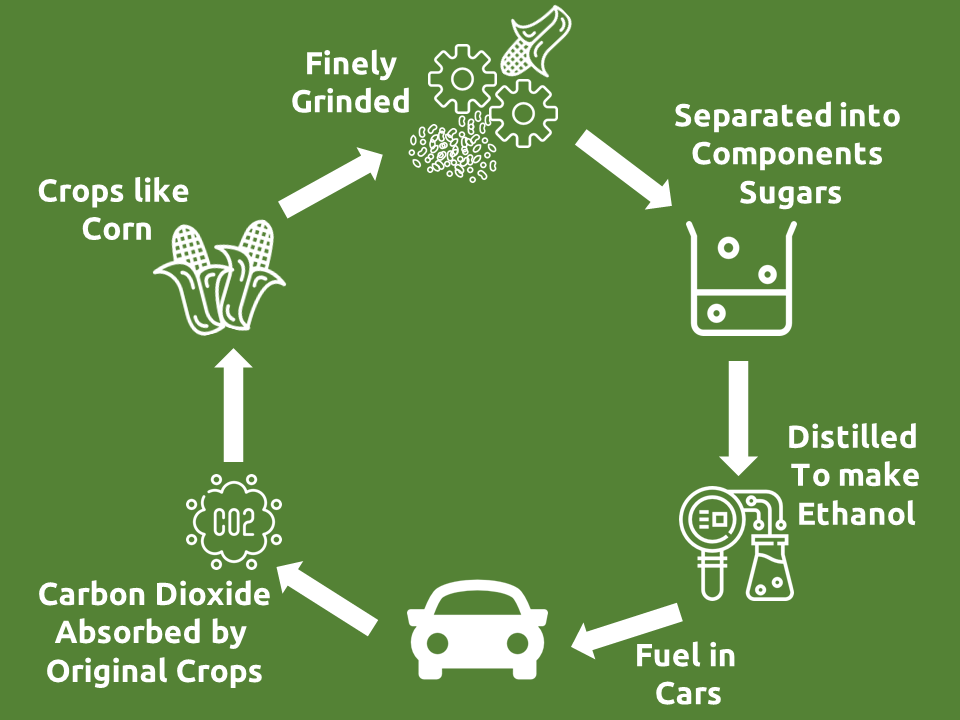

Mumbai, There are various types of bioethanol, sugarcane, namely 1G, 2G and 3G (First Generation, Second Generation & Third Generation) corresponding to various sources of raw material or biomass. Some countries have abundant sources of raw materials like corn seeds and sugarcane, which are used to produce 1G Bioethanol. In India, to keep food security within safe limits, 2G bioethanol derived from agricultural waste like corn cobs, rice husk and sugarcane bagasse is being promoted. 2G Bioethanol has two primary advantages: 1. Reduces incineration effect of agr-waste 2. Achieves the goal of wasting energy.

Speaking of the occasion, Shri. Kushal Banerjee, Chief General Manager, Hindustan Petroleum Corporation Ltd., Mumbai, who was invited as the chief guest quoted –

India plans to achieve a blending of 20% ethanol with 80% petrol by 2025 to help reduce its oil imports. India’s state-run refineries plan to build second-generation or 2G ethanol plants,

2 G Ethanol is produced using non-edible agricultural waste left over after harvesting. This can include corn cobs, rice straw and wheat straw, which is converted into cellulose and later fermented to form ethanol, which can be blended with conventional fuel.

To meet its 2025 target, India will have to almost triple ethanol production to about 10 billion litres a year to the country’s Secretary, MoPNG, Tarun Kapoor. This will require $7 billion of investment and the challenge would be to create the kind of capacity needed in a short span of three to four years. Beginning one plant would cost us 1000 crores. The government is offering financial support to sugar mills to set up or expand distilleries.

India is pursuing a similar strategy to Brazil, which has promoted sugarcane-based ethanol for more than 40 years to ease its sugar glut, cut dependency on oil imports and increase energy security. Today, Brazil owns the largest fleet of flex-fuel cars that can run on any blend of ethanol and gasoline.

India will also allow the production of ethanol-based flex engines. A flexible-fuel vehicle (FFV) or a dual-fuel vehicle is an alternative fuel vehicle with an internal combustion engine designed to run on over one fuel, usually, gasoline blended with either ethanol or methanol fuel, and both fuels are stored in the same common tank. Modern flex-fuel engines can burn any proportion of the resulting blend in the combustion chamber as fuel injection and spark timing are adjusted automatically according to the actual blend detected by a fuel composition sensor. Flex-fuel vehicles are distinguished from bi-fuel vehicles, where two fuels are stored in separate tanks and the engine runs on one fuel at a time, for example, compressed natural gas (CNG), liquefied petroleum gas (LPG), or hydrogen.

The most common commercially available FFV in the world market is the ethanol flexible-fuel vehicle, with about 63 million automobiles, motorcycles and light-duty trucks manufactured and sold worldwide and concentrated in four markets, Brazil, United States, Canada and Europe, led by Sweden.

India is pushing for more cars to run on ethanol. The government will fast-track an ethanol program that will divert as much as 6 million tons of sugar toward fuel production annually by 2025, according to the food ministry. That’s almost the entire amount that India, the world’s second-biggest producer after Brazil, currently exports to the global market.

“We at HPCL plan to set up four 2G ethanol plants which will convert thousands of tonnes of agricultural waste in northern India into biofuel, lessening toxic air pollution. HPCL has made provisions to set up four plants in which grains, like a surplus maze and surplus rice or damaged food grains, will make ethanol. We are setting up the 1st Second Generation (2G) Ethanol Biorefinery in Bathinda, Punjab. Down south, we have strategic equity investments in a Bangalore based Start-up – ASN Fuels for the establishment of a 2G Ethanol Pilot plant at Tirupati in collaboration with IIT Tirupati,” he was quoted as saying.

Among various other topics discussed, Professor Kishalay Mitra, IIT Hyderabad discussed India-wide Bio-Supply chain design under uncertainty, Dr Indulekha John, NIT Trichy produced papers on Study on ultrasound-assisted pre-treatment and hydrolysis for bioethanol production from musambi peel waste. Professors from IIT Madras, Kharagpur NIT Warangal, BVRIT Hyderabad, IIT Tirupathi ASN Fuels Pvt. Ltd. Bangalore were prominent speakers in the symposium who produced various research papers on the role and production of Ethanol in India. Various topics of discussion that included how green is 2G Bioethanol production, the feasibility analysis of bioethanol blending program, the significance of biomass drying in the production of bioethanol in India, flow properties of slurries encountered in 2G etc. were discussed to give an elaborate picture of how scientists and various researches are being done to show how much work is going into production of bioethanol and truly giving us clarity on the challenges in the production of 2G Bioethanol.

The symposium was concluded by a talk by Mr D.M. Naveen Giri, CEO ASN Fuels Pvt. Ltd. took us on a complete tour on the challenges and opportunities that have been created and worked upon by Indian start-ups like them to overcome the challenges of producing bioethanol in India.

Speaking on the occasion, he said “ASN Fuels has been an indomitable technocrat company with great passion in converting Agri-Industry waste. We are proud to be the first among the very few start-ups presently working on the Agricultural waste to Ethanol model with advancement in technology and implementation of pilot plant – 10LPD, action-driven, we are planning scale-up of our Pilot plant to – 2000 LPD mid-scale plant. Cluster-based – Waste to Energy approach with a focus on waste biomass generated by agri-processing industries like Rice mills, Corn seeds units, Sugar factories etc., leading to enormous volumes of Ethanol production across India. Locating 2G ethanol units right amid these agri-industry clusters to harness the logistical advantage is achievable by ASN’s versatile and dynamic TMR Technology scale from 20 to 50 KLPD.

Discussing the macro challenges and opportunities, he said that the current 2G ethanol projects are falling short of BIOMASS delivery to their units. Whereas cluster-based approach targeting the mid-scale (20-35 KLPD) 2G Ethanol Plants right in the middle of the agri-processing industry clusters gives us the logistical advantage of feedstock sourcing from these organised sectors. The Present purchase price for ethanol is ranging from Rs.50-65 / litre by the Oil Manufacturing Companies (OMC’s) makes it more difficult for the conventional 2G ethanol plants to meet out the cost expenditure ratios and end up in losses whereas strengthening Innovative technology gives us the advantage to produce 2G Ethanol at Rs. 40 / litre of ethanol making it an economically viable industry scale option. The conventional plants Capex are around 600-1000 cr- with the developing technology it can bring the CAPEX under 400 cr making it a commercially workable proposition. Developing technology adoption to the industry scale – timelines were the next major challenges.

We have found solutions for the other micro-challenges which involved pre-treatment, saccharification and fermentation processes. He also said that they have worked extensively on conventional strategies/scaling – drawbacks and the advantages of their research has enabled them to work towards the logistic cost and minimising complexity, easy scheduling of process operations, easy quality maintenance and hence making it an achievable target.

Easier said than done – establishment of 2G Bioethanol production units was not that easy. Hindustan Petroleum Corporation has promoted with equity investments ASN Fuels Pvt Ltd in collaboration with IIT-Tirupati Limited to try new avenues to produce ethanol from lignocellulosic biomass. Amid pilot plant development at Tirupati, Scientists at ASN Innovation centre carried out in-depth research successfully producing ethanol from fermentable sugars in the pipelines. ASN Fuels filed for patent loop Reactor Technology – in brief, is a long serpentine tubular reactor wherein fermentable sugars are converted to ethanol in the presence of brewer’s yeast. When pipeline reactor technology scaled up calculations were done to suit the industrial standards for an average rated capacity of 50KLPD Ethanol plant, experts pointed out a requirement of a few kilometres of pipeline. So, we thought, why not stretch this pipeline from the sugar factories to the nearest OMC’s ethanol blending depots with fermentation reaction going on inside it? The spark of an idea lighted up a fresh path to the striving ethanol industry – the Reactive Pipeline Technology. Adding to Mr Giri’s explanation, Dr Sunil Kumar, Assistant Professor, IIT- Tirupati said “Loop Reactor Technology has emerged as a fundamental change for both sugar factories and grain-based distilleries. At our pilot plant, we have also provided intermittent thermal equalisers to maintain the required pipeline temperature and also to scrub the reactively generated carbon dioxide which can be bottled and sold”.

The two-day symposium was convincingly concluded with a positive hope that we are at a striking distance of overcoming challenges in the production of 2G Bioethanol. It was a very insightful two-day symposium where a lot of ideas were exchanged and the Pros and Cons of making Ethanol easily available in India would soon be a reality and our dependency on Oil / Fuel would reduce to a great extent, thus making us Atmanirbhar Bharath.