We live in a world where we can easily spot a 10-year-old with a gadget, and to our surprise, kids are more tech-savvy than us. Even our grandparents these days rely on smartphones for their entertainment, thanks to the easy-to-use messenger app “WhatsApp” and that never-ending meme war going on in the family WhatsApp group. But what it does, and what we don’t notice and think about is, since the number of gadget users is increasing, what they’re leaving behind is a mountain of used gadgets, contributing to the constantly increasing amount of e-waste around us, which end up nowhere but in landfills.

But here’s the catch, how many of us really know that electronics are chock full of gold, and these days, looking at the amount of them dumped in landfills, we could find more of this precious metal in a landfill than in a mine. But getting it out is a polluting and expensive process, usually carried out at toxic dumps.

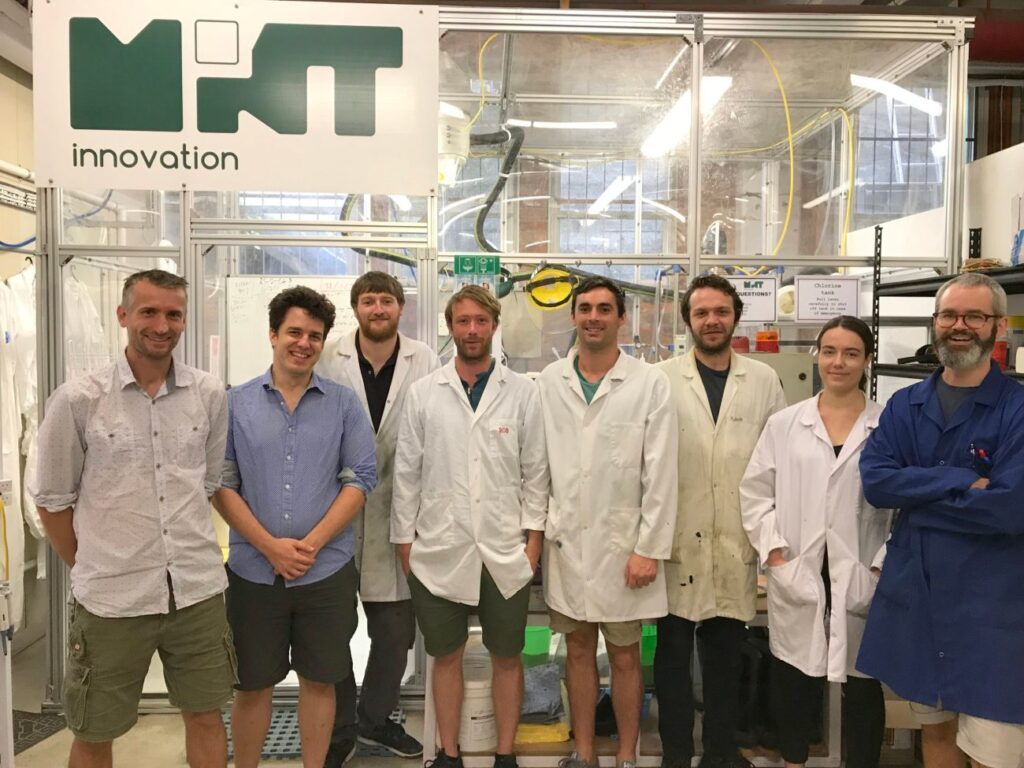

Mint Innovation, a New Zealand-based startup, has developed a safer and cleaner way to do that, and the secret ingredient to this process comes from nature, microscopic organisms evolved to absorb precious metals!

The extraction starts with circuit boards, which are found in almost every electronic device. The raw materials are sourced from a local recycler. “Exporting waste is an absolutely abhorrent thing for the human race to be doing”, says Will Barker, CEO and co-founder of Mint Innovation. According to him, if getting valuable metals from e-waste would somehow become easier, countries will start dealing with it locally.

First, circuit boards grin into a sand-like consistency and the workers put this sand into a reactor where they get mixed with inexpensive industrial chemicals. Then, machines pump this mixture into a filter press to separate the solid and liquid components. Mint uses electricity to pull the copper out of the separate liquid, which has a high concentration of other less valuable metals. But at this step of the process, palladium and gold are still stuck in the solid part as they’re harder to dissolve and need another chemical bath. The next step in their process definitely sets them apart from others. This is where microbes really come into play, to selectively concentrate precious metals. As several hours pass by, the microbes absorb precious metal ions and gain weight. When the paste dries out, the gold nanoparticles appear to be purple, thanks to its property of acquiring a purple-ish hue when put in small nanoparticles. Finally, the microbial part is burned and what’s left behind is 99.99% gold.

It takes about a week to pull out 150 grams of gold from a metric ton of circuit boards. But this, which seems like a lot of work for a little payoff, according to the founders, is totally worth it because it’s getting harder and harder to mine precious metals from the earth. And as gold mines are depleted, the amount of e-waste generated around the world is constantly increasing at a steady rate.

The company’s long-term goal is to make it easy and profitable for cities to process their e-waste locally and it is currently planning to expand full-scale facilities in Australia and the United Kingdom too.

Tazeen Ansari

A writer, an art enthusiast, and someone who can articulate her thoughts better while writing than speaking, is pretty much enough to describe Tazeen as a person.